Usoro mmepụta Margarine

Usoro mmepụta Margarine

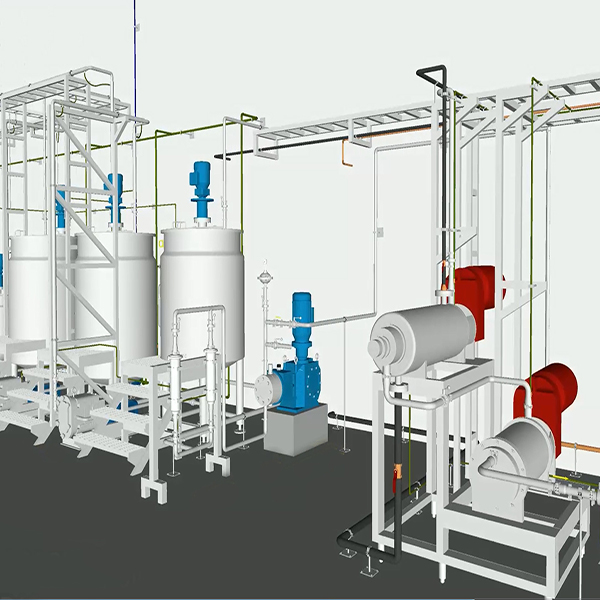

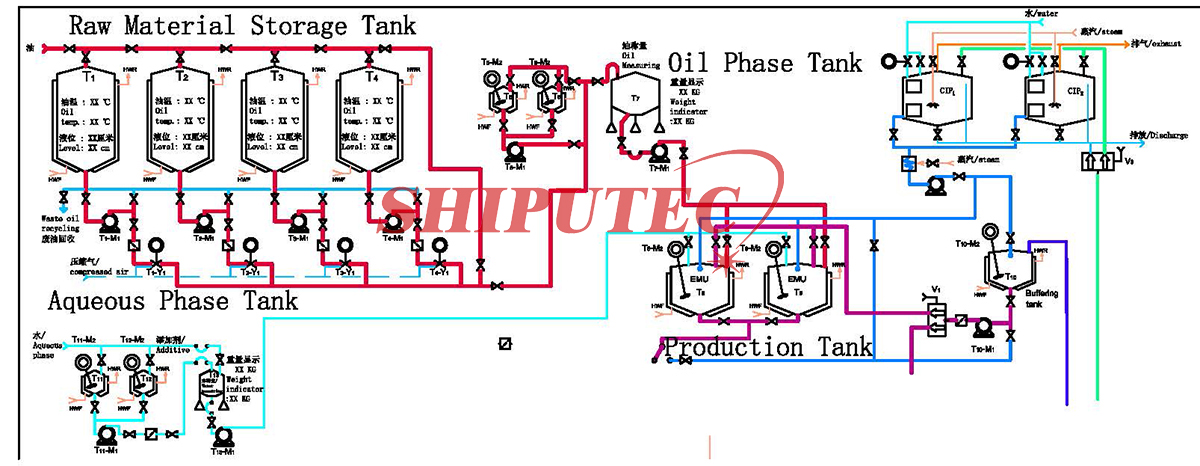

Mmepụta Margarine na-agụnye akụkụ abụọ: nkwadebe akụrụngwa na oyi na plasticizing. Akụrụngwa bụ isi gụnyere tankị nkwadebe, mgbapụta HP, votator (onye na-ekpo ọkụ n'elu ikpo ọkụ), igwe rotor pin, nkeji refrigeration, igwe na-ejuputa margarine na wdg.

Usoro mbụ bụ ngwakọta nke mmanụ mmanụ na mmiri mmiri, nha na emulsification ngwakọta nke mmanụ mmanụ na mmiri mmiri, iji kwadebe nri ihe oriri maka usoro ikpeazụ. Usoro ikpeazụ bụ plasticizing na-adị jụụ na-aga n'ihu na nkwakọ ngwaahịa.

E gosipụtara usoro nkwadebe akụrụngwa nke margarine na foto 1:

- 1.Mmiri ara ehi fermented

Ụfọdụ margarine usoro ịgbakwunye mmiri ara ehi, na mmiri ara ehi mgbe lactic acid bacteria gbaa ụka nwere ike na-emepụta yiri ekpomeekpo eke ude, otú factory ka fermented mmiri ara ehi na mmiri gwakọtara.

- 2.Ịgwakọta mmiri

A na-agbakwunye mmiri na mmiri-soluble mgbakwunye na usoro nke margarine, dị ka mmiri ara ehi fermented, nnu, preservatives, wdg, na-agbakwunyere na mmiri na-adọ agwakọta na metering tank n'ụzọ ziri ezi na-akpali akpali na mix, nke mere na mmiri na-adọ. components na-etisasịwo n'ime a edo ngwọta.

- 3.Ịgwakọta oge mmanụ

A na-ebu ụzọ gwakọta mmanụ raw nke nkọwa dị iche iche n'ime tankị na-agwakọta mmanụ dị ka oke a chọrọ, wee tinye ihe mgbakwunye mmanụ, dị ka emulsifier, antioxidant, pigmenti mmanụ na-edozi mmanụ, cellulose mmanụ-soluble, wdg. oge mmanụ dị ka oke nha, gwakọta ya na tankị metering, ma kpalie ka ọ bụrụ otu mmanụ mmanụ.

- 4.The emulsion

Nzube emulsification nke margarine bụ ime ka mmiri mmiri na-agbasa n'ụzọ ziri ezi na nke ọma na-agbasasị na mmanụ mmanụ, na ogo mgbasa ozi nke mmiri mmiri na-enwe mmetụta dị ukwuu na àgwà ngwaahịa ahụ. N'ihi na ekpomeekpo nke margarine nwere njikọ chiri anya na nha nke akụkụ mmiri mmiri, a na-eme mgbasa nke microorganisms na oge mmiri, nha nke nje bacteria n'ozuzu bụ 1-5 microns, ya mere, mmiri na-agbapụta na 10-20. microns ma ọ bụ obere nso nwere ike igbochi mgbasa nke nje bacteria, ya mere mgbasa nke mmiri na-adị oke mma, akụkụ mmiri nke mmiri dị ntakịrị ga-eme ka margarine kwụsị ekpomeekpo; Ịchụsa ezughị oke, akụkụ akụkụ mmiri dị oke ibu, ga-eme ka margarine mebie metamorphism. Mmekọrịta dị n'etiti ogo nke aqueous frasi dispersion na margarine na ọdịdị nke ngwaahịa bụ roughly dị ka ndị a:

| 水滴直径 Akụkụ mmiri dobe (Mikrometer) | 人造奶油性质 (Ire Margarine) |

| ihe na-erughị 1 (ihe dịka 80-85% nke usoro mmiri) | Dị arọ na obere ụtọ |

| 30-40 (ihe na-erughị 1% nke usoro mmiri) | Ụtọ dị mma, ọ dị mfe ime ihe |

| 1-5 (ihe dịka 95% nke usoro mmiri) | Ụtọ dị mma, ọ dịghị mfe ime ihe |

| 5-10 (ihe dịka 4% nke usoro mmiri) | |

| 10-20 (ihe dịka 1% nke usoro mmiri) |

Ọ nwere ike ịhụ na emulsification ọrụ kwesịrị iru a ụfọdụ ogo dispersion chọrọ.

Ebumnuche nke ịgwakọta oge mmiri na mmanụ mmanụ dị iche iche na nke mbụ na nke mbụ bụ iji hụ na emulsion dum na-ejikọta ya na ngwakọta nke mmanụ na mmiri ugboro abụọ. Emulsification Ịgwakọta bụ, ọrụ nsogbu bụ 50-60 degrees, mmiri na-adọ na-agbakwunyere na tụrụ mmanụ frasi, na n'ibu akpali akpali ma ọ bụ mgbapụta okirikiri akpali akpali, bụ mmiri na-adọ n'ụzọ zuru ezu gbasasịrị na mmanụ na-adọ, e guzobere latex. Ma ụdị mmiri mmiri latex a na-ejighị n'aka, kwụsị ịkpali nwere ike ịnọ n'ogige egwuregwu mmanụ na ihe nkewa mmiri.

Mgbe ebufechara emulsion agwakọta, a na-eme usoro jụrụ oyi na plastik ruo mgbe ejiri ngwaahịa ahụ.

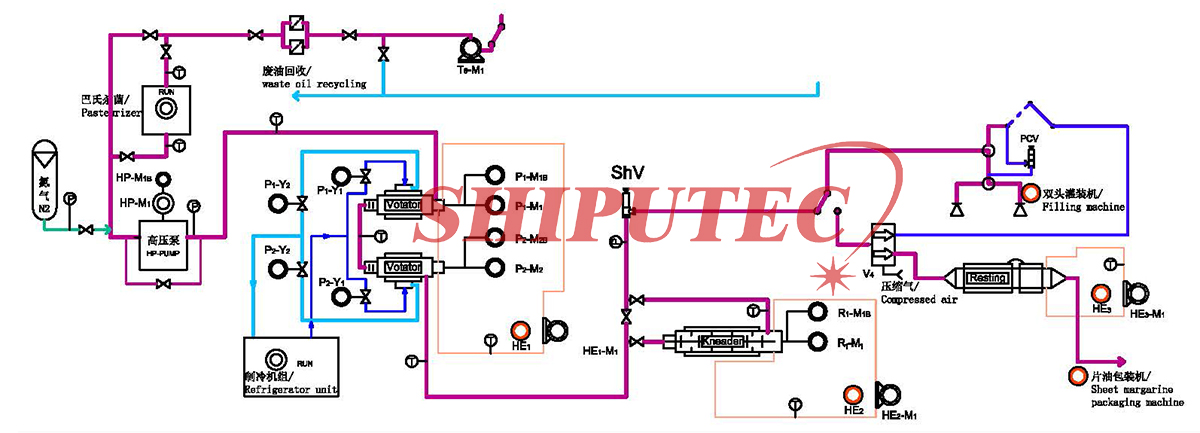

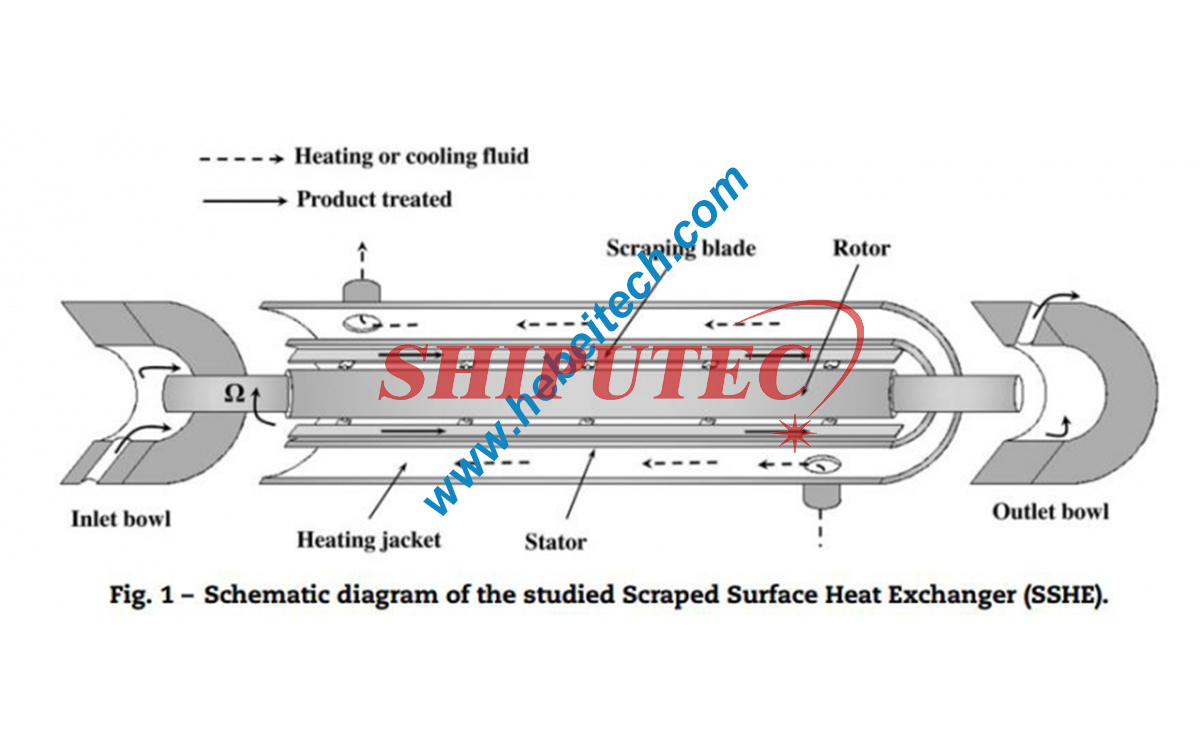

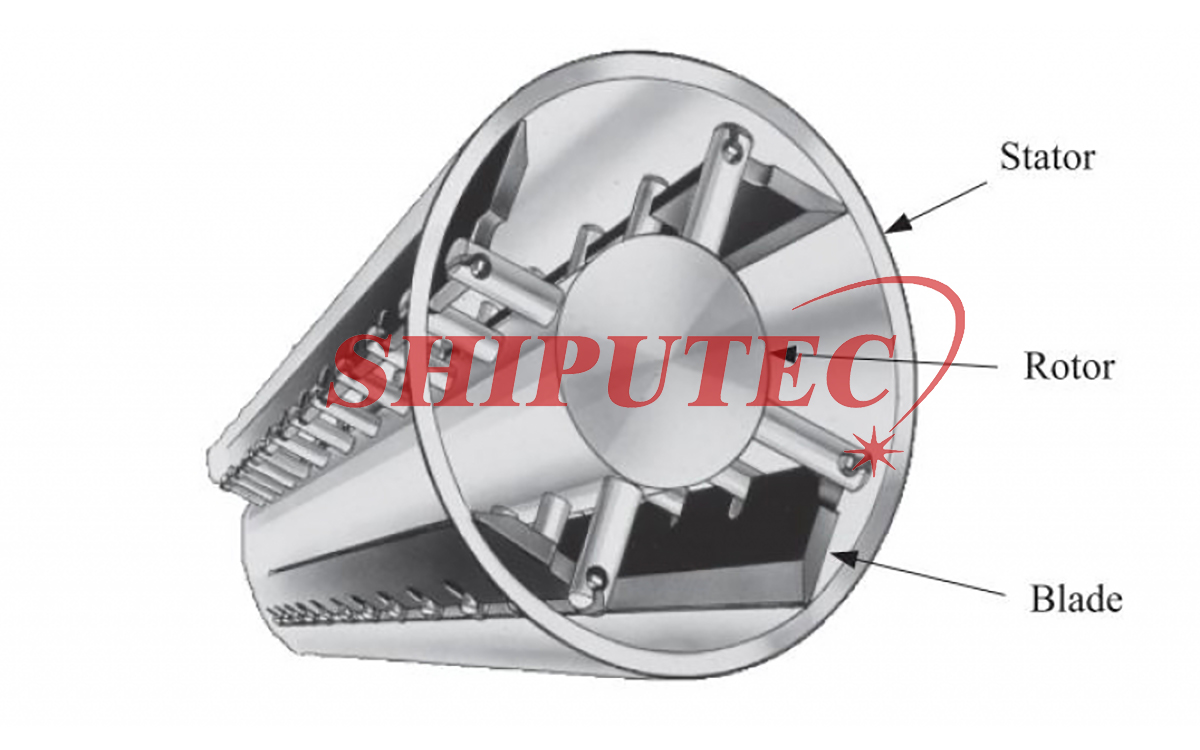

Emulsion ga-adị mma na plasticized iji mepụta ngwaahịa margarine na-agbanwe agbanwe. Ka ọ dị ugbu a, ọ na-anakwere ngwaọrụ plasticizing na-emechi emechi na-aga n'ihu, gụnyere votator ma ọ bụ nke a na-akpọ scraped surface heat exchanger (unit A), igwe rotor pin ma ọ bụ igwe igwakorita (unit C) na tube izu ike (unit B). E gosipụtara usoro teknụzụ na eserese 2:

Ngwa ngwa a nwere njirimara ndị a:

1. Nnukwu nrụgide ikuku na-aga n'ihu na-arụ ọrụ

A na-enye emulsion premixed n'ime cylinder quench site na mgbapụta nrụgide dị elu maka votator. Nrụgide dị elu nwere ike imeri nguzogide n'ime unit ahụ, na mgbakwunye na ọrụ nrụgide dị elu nwere ike ime ka ngwaahịa ahụ dị nro ma dị nro. Arụ ọrụ mechiri emechi nwere ike igbochi ikuku na ikuku n'ihi nkwụsị na ikuku mmiri nke agwakọta na emulsion, hụ na ngwaahịa ahụ ike chọrọ, belata nkwụsị nke refrigeration.

2. Quenching na emulsification

A na-emenyụ emulsion ahụ na amonia ma ọ bụ Freon na onye na-eme ihe iji mee ka emulsion dị jụụ ngwa ngwa, nke mere na mmepụta nke obere kristal kristal, n'ozuzu 1-5 microns, nke mere na uto dị nro. Ke adianade do, scraper na aro aro na votator nwere njikọ chiri anya na n'ime mgbidi nke cylinder, otú scraper na-arụ ọrụ nwere ike ọ bụghị nanị na-aga n'ihu scrape crystallization na-arapara n'ahụ mgbidi, ma na-eme ka emulsion gbasasịrị izute izute chọrọ emulsification nke ụda.

3. Kneading na dethickening (pin rotor igwe)

Ọ bụ ezie na emulsion jụrụ site na votator amalitela imepụta crystallization, ọ ka kwesịrị itolite site na oge. Ọ bụrụ na emulsion na-ekwe ka kristal na izu ike, netwọk nke kristal lipid siri ike ga-etolite. Ihe si na ya pụta bụ na emulsion jụrụ oyi ga-etolite oke siri ike na-enweghị plasticity. Ya mere, iji nweta margarine ngwaahịa na ụfọdụ plasticity, netwọk Ọdịdị ga-agbajikwa site n'ibu ụzọ tupu emulsion etolite mkpokọta netwọk Ọdịdị, nke mere na-enweta mmetụta nke mbenata ndim. A na-eme igwakorita na ikpochapụ oke na igwe rotor pin.

Unit A (votator) bụ n'ezie ngwaọrụ nju oyi. A na-ebuba emulsion ahụ n'ime nkeji mechiri emechi A (votator) site na mgbapụta nrụgide dị elu. Ihe na-agafe na ọwa n'etiti cylinder jụrụ oyi na ogwe na-atụgharị, na okpomọkụ ihe onwunwe na-adaba ngwa ngwa site na nkwụsị nke ihe na-ajụ oyi. A na-ahazi ahịrị abụọ nke scrapers n'elu osisi. A na-ekpochapụ kristal ndị a kpụrụ n'elu ime nke onye na-eme votator site na scraper na-agbagharị ọsọ dị elu iji kpughee elu ọhụrụ ahụ dị jụụ mgbe niile ma nọgide na-ebufe okpomọkụ nke ọma. Enwere ike ịgbasa emulsion n'okpuru ọrụ nke scraper. Mgbe ihe na-agafe na unit A (votator), okpomọkụ na-adaba na 10-20 degrees, nke dị ala karịa ebe mgbaze nke mmanụ. Ọ bụ ezie na mmanụ ahụ na-amalite kristal, ọ kabeghị ọnọdụ siri ike. N'oge a, emulsion dị na ọnọdụ nke jụrụ oyi na ọ bụ nnukwu mmiri mmiri.

Axis ntụgharị nke unit A (votator) nwere oghere. N'oge a na-arụ ọrụ, a na-agbanye mmiri ọkụ nke 50-60 degrees n'ime etiti nke ntụgharị ntụgharị iji gbochie crystallization bonded na gwọọ na axis na-akpata mgbochi.

Unit C (igwe rotor pin) na-akpụkọ ma na-ewepụ ihe dị arọ, dị ka egosiri na foto dị n'elu. A na-etinye ahịrị abụọ nke ígwè ígwè na-atụgharị na-atụgharị, a na-etinyekwa ahịrị ígwè nke edozi isi na mgbidi dị n'ime nke cylinder ahụ, nke a na-eji ígwè na-agbanye ígwè na ogwe aka ma ghara imetụ ibe ya aka. Mgbe ogwe ahụ na-agbagharị na nnukwu ọsọ ọsọ, ihe mkpuchi ígwè na-agafe na oghere nke ihe nkwụnye ígwè edozi, na ihe a na-ejikọta ya kpamkpam. N'okpuru omume a, ọ nwere ike ịkwalite uto nke kristal, mebie usoro netwọk kristal, mepụta kristal na-akwụsị akwụsị, belata nkwụsi ike, ma mee ka plasticity dịkwuo elu.

Unit C (igwe rotor pin) na-arụ naanị mmetụta igwakota agwa n'abalị dị oke oyi, yabụ na ọ chọrọ naanị nchekwa ọkụ na ọ chọghị ka ọ dị jụụ. Dị ka a na-ahapụ okpomọkụ crystallization (ihe dị ka 50KCAL / KG), na ọkụ na-eme ka esemokwu na-eme ka ọkụ na-ekpo ọkụ, okpomọkụ nke unit C (pin rotor macjhine) dị elu karịa nke okpomọkụ nri. N'oge a, crystallization bụ ihe dị ka 70% zuru ezu, ma ọ ka dị nro. A na-ahapụ ngwaahịa ikpeazụ site na valvụ extrusion, ọ ga-esikwa ike mgbe oge ụfọdụ gasịrị.

Mgbe ezipụ margarine site na unit C (pin rotor machine), ọ dị mkpa ka a gwọọ ya na okpomọkụ. N'ozuzu, a na-etinye ngwaahịa ahụ na okpomọkụ nke ogo 10 n'okpuru ebe mgbaze maka ihe karịrị awa 48. A na-akpọ ọgwụgwọ a ripening. Enwere ike izipu ngwaahịa esi nri ozugbo na ụlọ ọrụ nhazi nri maka ojiji.